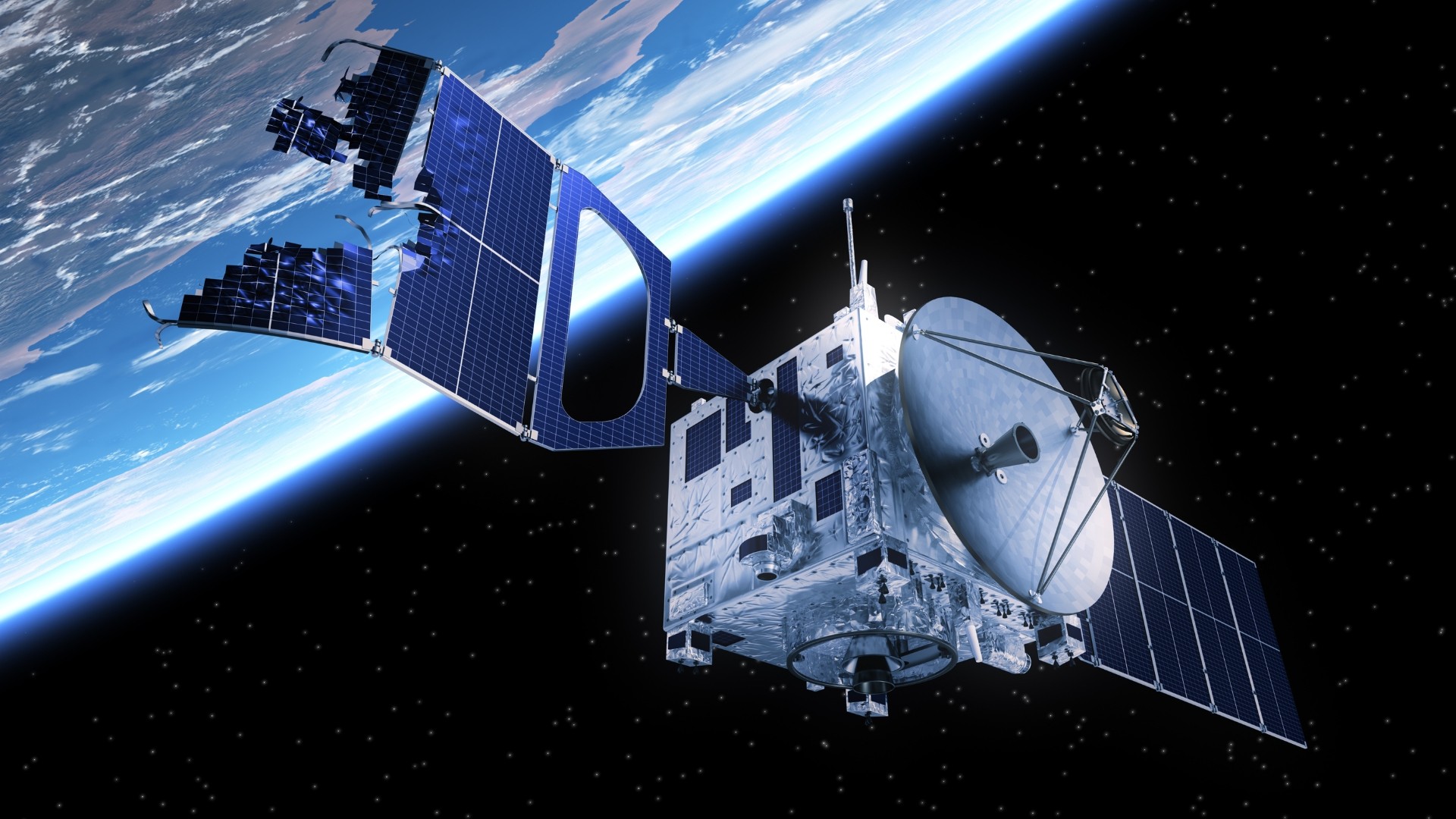

Surveying of facilities and inspections using Low Earth Orbit (LEO) satellites involves the use of satellites in low-altitude orbits to gather information about various structures, facilities, or geographical areas on Earth. LEO satellites are positioned at altitudes ranging from approximately 180 to 2,000 kilometres above the Earth's surface.

Businesses with extensive infrastructure, such as utilities, oil and gas facilities, and telecommunications networks, can utilize LEO satellite imagery for regular inspections. High-resolution images can help identify potential issues, such as equipment wear and tear, leaks, or structural damage. This proactive approach allows companies to schedule maintenance activities more efficiently, reducing downtime and the risk of unexpected failures.

LEO satellites typically have short orbital periods, resulting in rapid revisit times. This frequent revisit capability enables near real-time monitoring, making it possible to detect changes, assess conditions, and respond quickly to evolving situations.

LEO satellites can capture high-resolution images, providing detailed and clear visuals of structures and facilities. This allows for precise analysis and identification of specific features, potential issues, or changes over time.

LEO satellites can offer continuous monitoring of structures and facilities, allowing for ongoing assessment of conditions and performance. This continuous surveillance is particularly beneficial for critical infrastructure, where timely detection of issues is essential for maintenance and safety.

LEO satellites can capture data in various spectrums, including visible, infrared, and thermal. This multispectral capability enables a more comprehensive analysis of structures, allowing for the identification of issues such as heat leaks, structural weaknesses, or environmental impacts.

LEO satellite imagery is invaluable in emergency response and disaster management. It provides quick assessments of damage to structures following events, facilitating rapid decision-making and efficient allocation of resources for rescue and recovery efforts.

Satellite-based surveys eliminate the need for physical presence on-site, reducing costs associated with travel, personnel, and equipment. The ability to cover large areas in a single pass enhances cost-effectiveness.

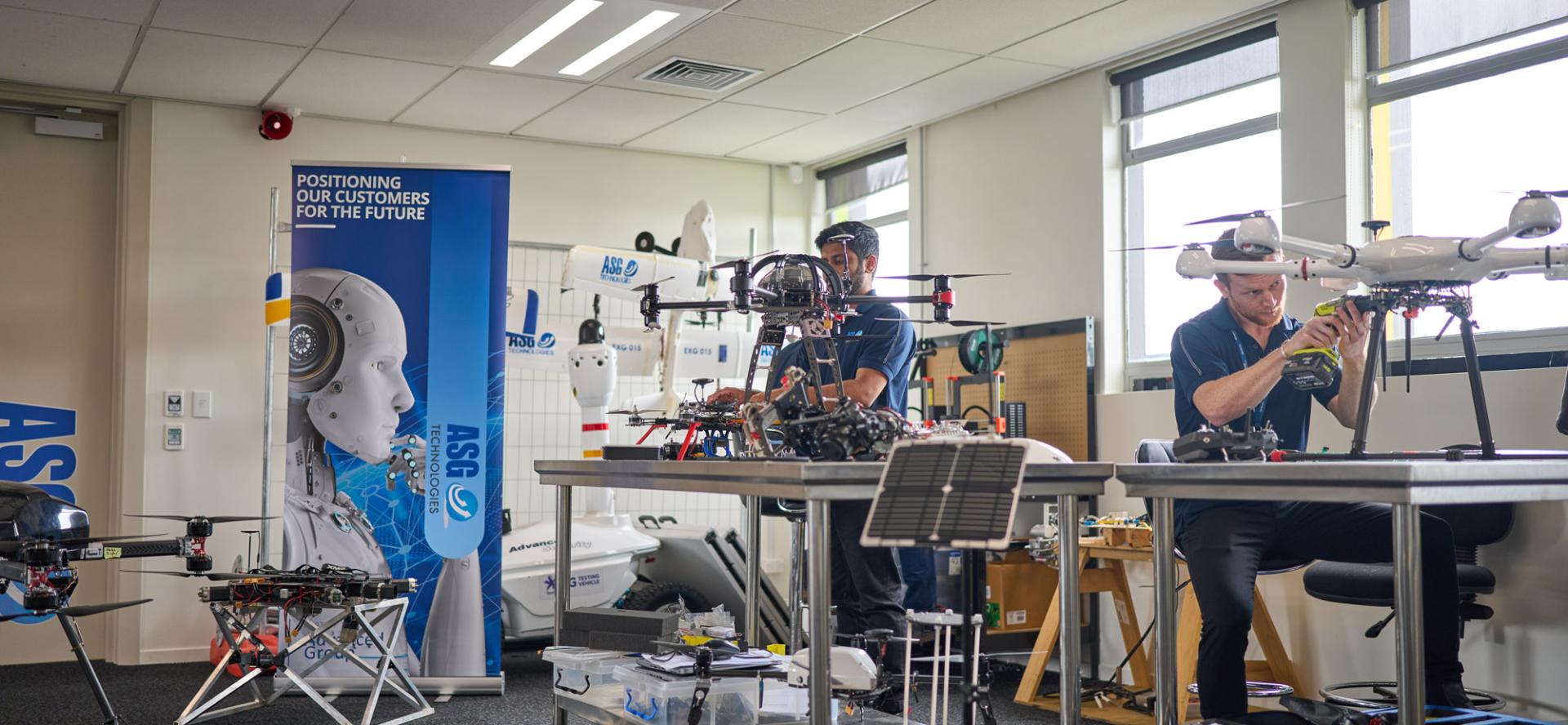

With years of experience in the aerial survey domain, ASG Tech stands as a beacon of expertise and innovation. Our team of dedicated professionals, equipped with the latest technology, is committed to delivering excellence. Our portfolio of successful projects across various industries testifies to our competence and dedication in this space.

We have the expertise to help. Get in touch with our team today.

Advanced Group

PO Box 12236, Penrose

Auckland 1642, New Zealand

Advanced Group Phone

©2024 Advanced Group. Site by RAZOR Web Design